Working on DIY projects around the house or tackling professional tasks can be a breeze with the right tools. A reliable air compressor is a staple in any workshop, offering power and versatility for a range of applications. But when it comes to maintaining and troubleshooting your trusty compressor, understanding its inner workings is crucial. This is where a Central Pneumatic 21 gallon air compressor parts diagram comes in handy. It’s a valuable resource that helps you navigate the intricate components within your machine, empowering you to perform basic maintenance, identify potential issues, and even carry out minor repairs.

Image: atelier-yuwa.ciao.jp

Having a central pneumatic 21 gallon air compressor parts diagram can be a lifesaver when you encounter unexpected problems. Whether it’s a leaking hose, a malfunctioning pressure switch, or a noisy motor, having a clear visual representation of the components can make all the difference in pinpointing the source of the issue. By understanding the relationship between various parts and their functions, you can effectively diagnose problems and find the right solutions.

Navigating the Central Pneumatic 21 Gallon Air Compressor Parts Diagram: A Comprehensive Guide

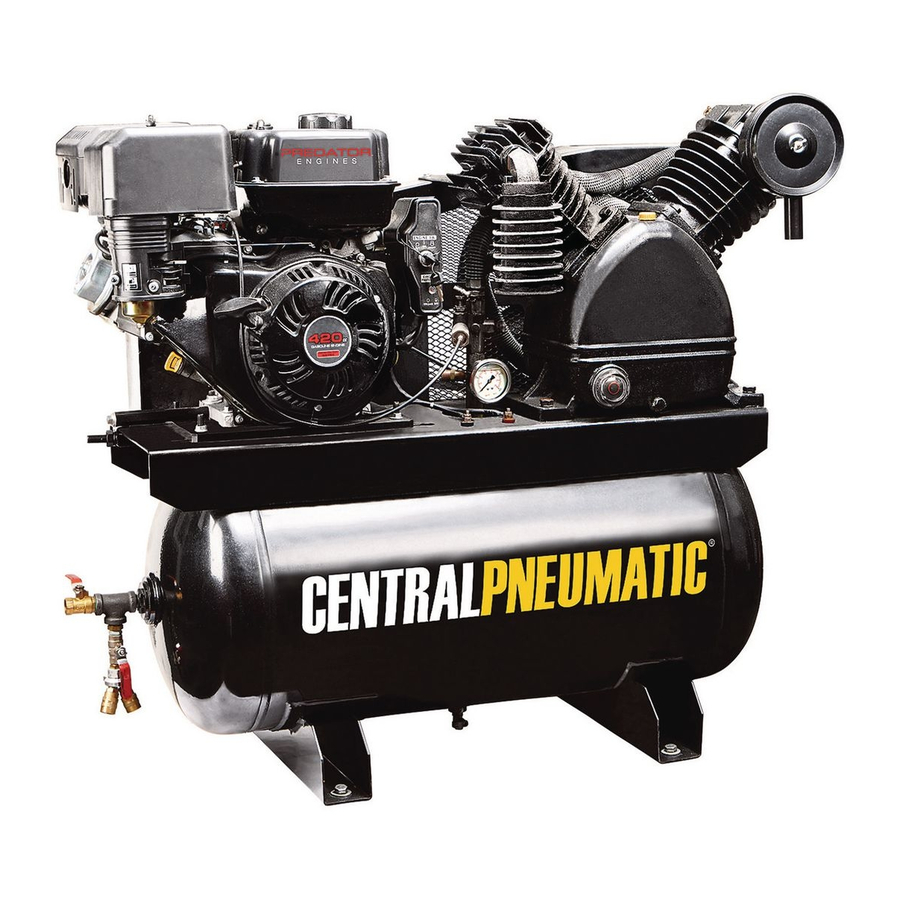

The Central Pneumatic 21 gallon air compressor is a popular choice among both hobbyists and professionals due to its durability, performance, and affordability. This model boasts a robust design featuring a powerful motor, a spacious air tank, and a range of essential components that ensure smooth and efficient operation. To understand these components better, we’ll delve into a detailed exploration of a typical Central Pneumatic 21 gallon air compressor parts diagram.

Understanding the Core Components

The Motor

The heart of any air compressor is the motor, which is responsible for driving the piston and compressing the air. In the Central Pneumatic 21 gallon air compressor, you will typically find an oil-lubricated, single-phase induction motor. This type of motor provides reliable and durable performance, ensuring long-lasting operation. The motor’s power output is crucial for determining the compressor’s performance, indicated by the horsepower rating. Generally, the higher the horsepower, the more powerful the compressor will be.

Image: www.youtube.com

The Air Tank

The air tank is where the compressed air is stored. The larger the air tank, the more air can be stored, meaning you will have more air available for your tools before the compressor needs to cycle back on. In the Central Pneumatic 21 gallon air compressor, the tank is a crucial element, offering significant storage capacity, ensuring prolonged use without experiencing repeated cycles, which can be detrimental to the compressor’s life.

The Pressure Switch

The pressure switch is responsible for controlling the compressor’s on/off cycle. With the switch, a preset level of pressure will trigger the compressor to turn on, and once the desired pressure is reached, the compressor is turned off. The pressure switch is a crucial safety feature, ensuring that the compressor doesn’t run continuously, which can lead to overheating and damage.

The Regulator

The regulator allows you to adjust the output pressure of the compressor. This is essential for various applications, as different tools require varying pressure levels for optimal performance. Proper use of the regulator helps prevent damage to tools or your workpieces caused by excessive pressure.

The Unloader Valve

The unloader valve relieves the pressure in the air tank during the off cycle. When the compressor is not running, the unloader valve opens, allowing air to escape from the tank, which eases the workload on the motor when it restarts. The unloader is also crucial for preventing damage to the components caused by excessive pressure build-up during non-operational periods.

The Air Filter

The air filter is a crucial element for ensuring clean air enters the compressor. It screens out dust, debris, and other contaminants that can damage the compressor’s internals, including the motor and the piston. Regularly cleaning and replacing the air filter is an essential step in maintaining your compressor’s optimal performance.

Essential Tools for Maintenance

To effectively maintain your Central Pneumatic 21 gallon air compressor, having the right tools is essential. Here are a few items that should be in your toolbox:

- A set of wrenches and sockets to tighten or loosen fittings and bolts

- A screwdriver for loosening and tightening screws

- An air pressure gauge to check the pressure in the air tank

- A lubricant for lubricating moving parts

Tips for Maintaining Your Compressor

The Central Pneumatic 21 gallon air compressor is a robust machine with a long lifespan if properly cared for. Here are a few tips to keep your compressor running smoothly:

- Change the air filter regularly: A clean air filter is essential for optimal performance and longevity. Replace it according to the manufacturer’s instructions or if it becomes clogged with dirt and debris.

- Drain the air tank regularly: Over time, condensation can build up in the air tank, which can lead to rust and corrosion. Draining the tank regularly, once every few weeks, will help prevent this.

- Lubricate the motor: The motor of the Central Pneumatic 21 gallon air compressor needs regular lubrication. Refer to the instruction manual for the type of lubricant and the frequency of lubrication. Proper lubrication helps ensure smooth operation and extends the life of the motor.

- Check the pressure switch setting: The pressure switch setting ensures proper pressure regulation. Ensure it’s set to the manufacturer’s recommended level for optimal performance.

- Inspect the hoses and connections: Check the hoses and connections for any signs of wear, tear, or leaks. Replace damaged or leaking hoses and connections immediately.

FAQ’s

Q: What is the purpose of the central pneumatic 21 gallon air compressor parts diagram?

A: The parts diagram provides a visual representation of all the components of your compressor. It allows you to understand how the various parts interact, making it easier to identify potential problems and carry out repairs.

Q: How often should I change the air filter in my Central Pneumatic 21 gallon air compressor?

A: The frequency of air filter changes depends on the usage and environment of your compressor. Check the manufacturer’s instructions or inspect the filter for dirt build-up. Replace it if it becomes noticeably clogged.

Q: Where can I find the central pneumatic 21 gallon air compressor parts diagram?

A: You can typically find the parts diagram in the owner’s manual or on the manufacturer’s website. If those options aren’t available, you can often find diagrams online through reputable websites or retailers that sell Central Pneumatic products.

Central Pneumatic 21 Gallon Air Compressor Parts Diagram

Conclusion

Understanding your Central Pneumatic 21 gallon air compressor parts diagram is key to keeping it running smoothly. By familiarizing yourself with the components and their functions, you can perform essential maintenance, troubleshoot problems, and extend the life of your valuable tool. Whether you are a seasoned DIY enthusiast or a professional contractor, a good understanding of your air compressor’s parts will ensure years of reliable performance.

Did learning about the central pneumatic 21 gallon air compressor parts diagram help you? Let us know your thoughts in the comments below.