Have you ever wondered what makes a Cummins ISX engine tick? These powerful workhorses are the heart of many heavy-duty trucks, and understanding their intricate workings can be crucial for both professional drivers and mechanics. This article delves into the fascinating world of the Cummins ISX engine, focusing specifically on sensor location and the comprehensive parts diagram that helps to unravel its inner workings.

Image: favpng.com

Whether you’re a seasoned mechanic looking to diagnose a complex engine issue or a curious enthusiast eager to grasp the intricacies of this marvel of engineering, our guide will provide you with the knowledge and insights you need. We’ll explore the layout of the ISX engine, pinpoint the vital role of each sensor, and explore the importance of a detailed parts diagram in understanding its internal architecture.

Navigating the Labyrinth: The Cummins ISX Engine Layout

The Cummins ISX engine is a marvel of engineering, meticulously designed to deliver exceptional performance and reliability. To understand the location of its sensors, it’s essential to first grasp its fundamental layout. The ISX is a six-cylinder, in-line engine, meaning its cylinders are arranged vertically in a single row. Each cylinder houses a piston that transforms the explosive force of combustion into mechanical energy, driving the crankshaft that ultimately powers the vehicle.

The Nervous System: Sensors and Their Significance

Sensors act as the nervous system of the Cummins ISX engine; they constantly monitor critical parameters, providing the engine control unit (ECU) with the data it needs to make real-time adjustments for optimal performance. Here’s a breakdown of some key sensors and their roles:

1. Crank Position Sensor (CPS): The Heartbeat of the Engine

The CPS is situated at the front of the engine, directly near the crankshaft. This sensor detects the angular position of the crankshaft, providing crucial timing information to the ECU. Think of it as the engine’s pacemaker, ensuring a smooth and synchronized firing sequence for each cylinder.

![[DIAGRAM] Willys 475 Wiring Diagrams - MYDIAGRAM.ONLINE](https://ww2.justanswer.com/uploads/cumminsdr/2012-03-17_193524_19c005871.png)

Image: mydiagram.online

2. Cam Position Sensor (CPS): Orchestrating Valve Timing

The cam position sensor is strategically positioned near the camshaft, responsible for tracking its rotational position. The camshaft controls the opening and closing of the valves, which regulate the flow of air and fuel into the cylinders. The CPS ensures the valves open and close at precisely the right time, maximizing fuel efficiency and combustion efficiency.

3. Intake Air Temperature Sensor (IAT): Monitoring Incoming Air

The IAT sensor is typically positioned in the intake manifold, measuring the temperature of the air entering the cylinders. The ECU uses this information to optimize fuel injection timing and air-fuel ratios based on temperature variations.

4. Coolant Temperature Sensor (CTS): Keeping the Engine Cool

The CTS, situated in the engine’s cooling system, monitors the coolant temperature. This sensor plays a vital role in controlling the engine’s cooling system, ensuring the engine operates within safe temperature limits to prevent overheating.

5. Boost Pressure Sensor: Gauging Turbocharger Performance

The boost pressure sensor is typically located near the intake manifold, measuring the pressure generated by the turbocharger. This information helps the ECU adjust fuel injection timing, optimize combustion, and maximize engine power.

6. Exhaust Gas Temperature Sensor (EGT): Monitoring Heat After Combustion

The EGT sensor is installed in the exhaust manifold, measuring the temperature of the exhaust gases. This data provides valuable insights into combustion efficiency and helps the ECU adjust engine parameters to optimize performance and emissions control.

7. Fuel Pressure Sensor: Regulating Fuel Delivery

The fuel pressure sensor is found in the fuel system, monitoring the pressure at which fuel is delivered to the injectors. This information is critical for controlling fuel injection quantities and ensuring proper combustion conditions.

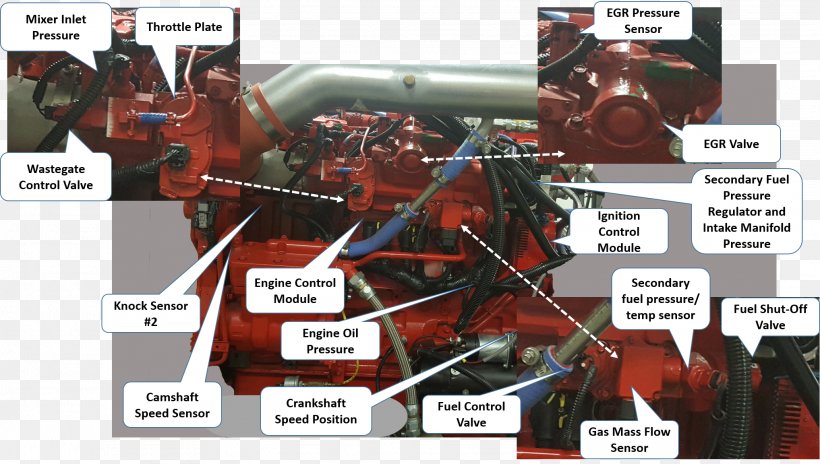

Deciphering the Language: Reading the Parts Diagram

A parts diagram is an indispensable tool for understanding the intricate workings of the ISX engine. It’s like a blueprint that maps out every component and its location. Carefully studying the parts diagram can help you identify specific sensors, their positions, and how they interact with other engine components.

1. Locating Sensors on the Parts Diagram: A Visual Guide

The parts diagram is essentially a visual map of the engine, showcasing its components in their correct positions. Sensors are typically represented by specific symbols or labels that clearly indicate their location. By referencing the diagram, you can easily track down any sensor you need to access or diagnose.

2. Understanding Sensor Connectivity: The Flow of Information

The parts diagram also reveals the connectivity of sensors, indicating how they’re wired and connected to the ECU. This information is essential for tracing electrical circuits, troubleshooting electrical problems, and ensuring proper sensor functionality.

3. Parts Identification: Navigating the ISX Engine Inventory

The parts diagram serves as a comprehensive index of all engine parts, providing part numbers, descriptions, and other important details. This feature allows you to easily identify components, locate replacement parts, and understand the relationship between various engine elements.

Navigating Through the Digital Age: Online Resources

The digital age has revolutionized our access to information, and engine components are no exception. Numerous online resources offer detailed parts diagrams for the Cummins ISX engine, enabling you to explore the intricacies of this powerhouse in the comfort of your own home. These digital platforms often provide interactive diagrams with zoom capabilities, enhancing visibility and allowing for a thorough exploration of every part.

1. Manufacturer Websites: The Ultimate Source

The Cummins website is an invaluable resource for accessing official parts diagrams and technical documentation for the ISX engine. This platform provides accurate and up-to-date information directly from the manufacturer, ensuring the highest level of reliability.

2. Third-Party Resources: Expanding Your Knowledge

A plethora of third-party websites offer comprehensive parts diagrams for the ISX engine, providing valuable insights and complementary information. These websites often offer additional features, such as 3D visualizations, interactive functionalities, and comparative analyses, enhancing your understanding of the engine’s internal structure.

Sensor Location Cummins Isx Engine Parts Diagram

https://youtube.com/watch?v=fgpIQXTk7j8

The Importance of Understanding Sensor Location and Parts Diagram

By comprehending the layout and function of sensors within the Cummins ISX engine, you gain a valuable understanding of its critical systems and operational principles. This knowledge equips you with the tools to diagnose potential problems, troubleshoot engine issues, and ensure optimal performance. Moreover, familiarity with the parts diagram allows you to confidently identify and order replacement parts, ensuring smooth operation and efficient maintenance.

Whether you’re a seasoned mechanic, a truck owner, or an individual fascinated by the intricacies of machinery, the ability to decode the Cummins ISX engine is an invaluable skill. By equipping yourself with the knowledge to navigate its sensor locations and interpret its parts diagram, you empower yourself to unlock the full potential of this powerful workhorse.