The whirring of a drill press, the precise movements of the drill bit, and the satisfying sound of metal being shaped—this is the symphony of a workshop, and at its heart lies a powerful tool: the drill press. It’s more than just a drill; it’s a precision instrument capable of drilling holes with incredible accuracy and consistency. But before you can master the drill press, you need to understand its various components and how they work together.

Image: www.finepowertools.com

A few years back, I was trying to create perfectly aligned holes in a wooden project for a shelf I was building. I struggled with a handheld drill, the results were far from precise. Then, I discovered the drill press, and it was like a revelation! The ease with which it handled the task, the accuracy, and the control it offered were incredible. That’s when I realized how important understanding the parts of a drill press is to making the most of this indispensable tool.

Understanding the Anatomy of a Drill Press

A drill press is a sturdy machine that comprises various components, all of which play a critical role in its operation. Let’s break down its anatomy:

The Base

The foundation of any drill press, the base is usually made of cast iron, providing stability and weight to prevent the machine from wobbling during operation. It forms the base platform on which the entire drill press structure rests. This sturdy foundation guarantees the accuracy and smoothness of drilling operations.

The Column

Rising from the base is the column, a vertical structure that houses the motor and supports the entire drilling mechanism. The column acts as a rigid upright that ensures the precision of vertical drilling movements. It’s made of durable materials to withstand the stress of drilling operations.

Image: reviewmotors.co

The Head

The head sits at the top of the column and houses the motor, the spindle, and the quill. This is where the power and movement come together.

The Motor

The motor provides the power to the entire system. It spins the spindle, which in turn rotates the drill bit. Electric motors are commonly used in drill presses but you can also find some with belt-driven motors.

The Spindle

The spindle is the rotating rod that holds the drill bit. It’s attached to the motor and rotates at high speeds, transmitting the power to the drill bit. Its smooth and precise rotation ensures accurate drilling.

The Quill

The quill is a cylindrical tube that houses the spindle and allows for vertical movement. It slides up and down along the column, allowing you to adjust the drilling depth. This depth control mechanism is essential for achieving precise drilling results.

The Table

The table sits on top of the base and serves as the platform for your workpiece during drilling. It’s usually made of cast iron with slots and T-slots for holding workpieces securely in place. The table can be adjusted for height to accommodate different-sized workpieces.

The Drill Press Chuck

The chuck is a device that holds the drill bit securely. It’s mounted to the spindle and allows you to quickly change drill bits. The chuck is a crucial component in ensuring the accuracy and safety of drilling operations.

Maximizing Performance: Tips for Mastering Your Drill Press

Now that you understand the components of a drill press, let’s look into some tips to ensure safe and effective operation:

Safety First

Safety should always be your top priority when working with any power tool, especially a drill press. Always use safety glasses to protect your eyes from flying debris. Wear a dust mask to prevent inhaling dust particles. Secure your workpieces firmly to the table with clamps or vise to avoid accidents.

Proper Setup

Take the time to set up your drill press correctly. Ensure the table is level and the spindle is perpendicular to the table. Adjust the drilling depth and speed according to the material being drilled.

Lubrication

Lubricate the quill and spindle regularly to prevent friction and wear. Use appropriate lubricants recommended by the manufacturer.

Drill Bit Selection

Choose the right drill bit for the material you’re drilling and the size of the hole you need. Use a sharp bit to ensure clean, accurate holes and minimize the risk of breaking the bit.

Drilling Techniques

Apply gentle pressure while drilling, gradually increasing the pressure as the bit penetrates the material. Avoid forcing the drill bit, as this can cause it to break or create an uneven hole. For deeper holes, use a pilot hole and gradually increase the drill bit size.

Common Drill Press Questions Answered

Here are some frequently asked questions about drill presses:

Q: What are the different types of drill presses?

A: There are various types, including floor and benchtop drill presses, radial drill presses, and magnetic drill presses. Each type has its unique features and applications, so it’s important to choose the right one for your needs.

Q: What are some common drill press accessories?

A: Drill press accessories include drill chucks, drill bits, drill press vises, fences, and depth gauges. These accessories can further enhance functionality and safety.

Q: How do I maintain my drill press?

A: Regular maintenance involves cleaning the drill press, lubricating moving parts, and inspecting the belts and pulleys.

Q: What are some safety precautions to take when using a drill press?

A: Always wear safety glasses, a dust mask, and hearing protection. Secure your workpieces firmly to the table. Never reach into the drilling area while the drill press is running. Be aware of your surroundings and be careful about any loose clothing or jewelry.

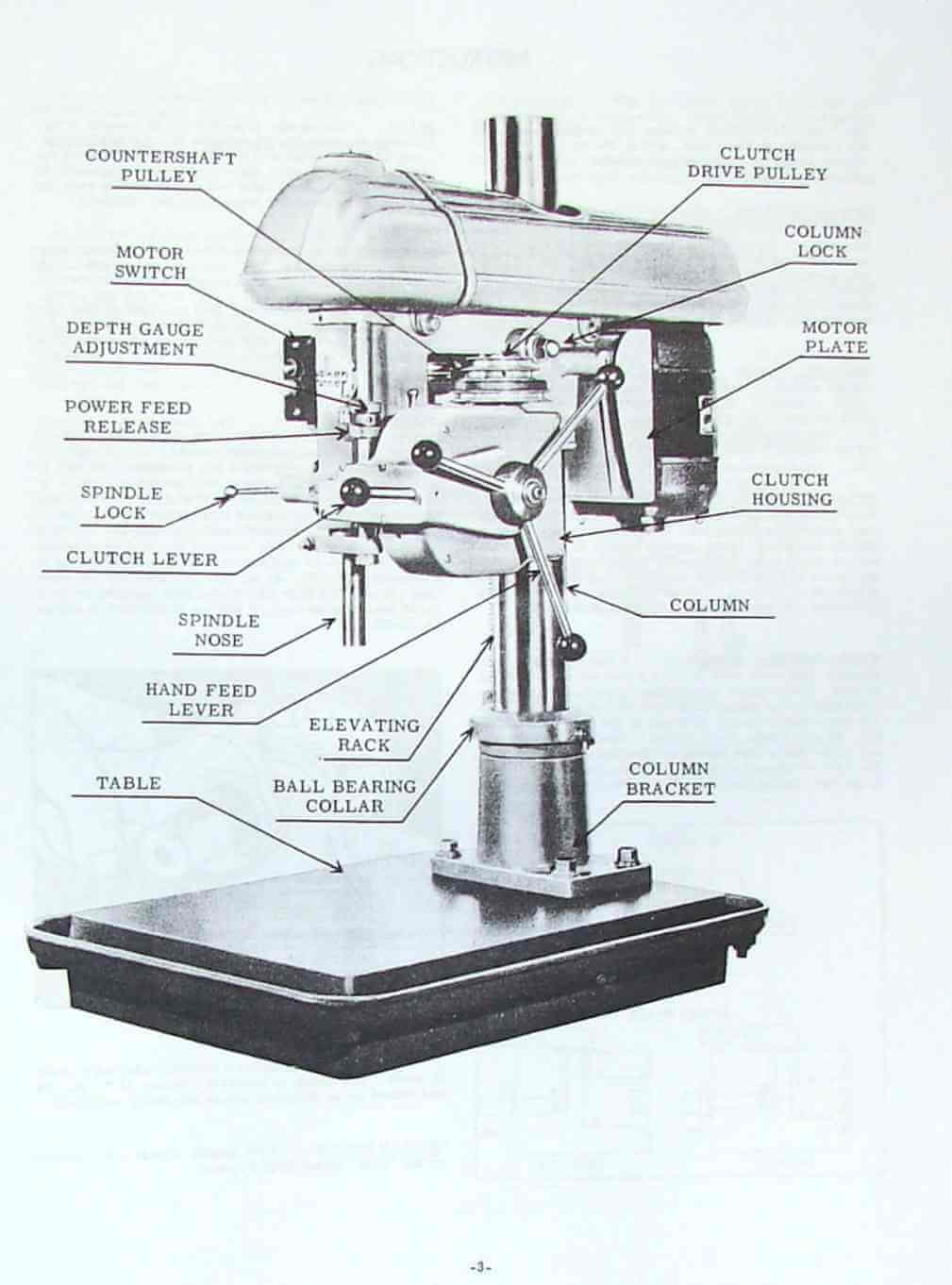

Parts Of A Drill Press Diagram

Conclusion: Unleash the Power of Precision Drilling

Understanding the parts of a drill press is crucial to mastering your skills with this powerful tool. From the sturdy base to the precise drilling mechanism, each component plays a vital role in producing accurate and reliable holes. By understanding these components, implementing safe practices, and utilizing the right accessories, you can maximize the performance of your drill press. So, are you ready to dive into the world of precision drilling? Tell us in the comments below!